Mechanical plant and equipment are essential for modern developments — but they come with a hidden cost: noise. Failing to control it can halt your project before it begins. Whether you’re installing air source heat pumps, rooftop AHUs, or generator systems, acoustic attenuators are one of the most effective ways to mitigate noise and satisfy planning conditions. In this post, we explore how acoustic attenuators can help you pass BS4142 noise assessments, avoid costly objections, and keep your development on track.

What Are Acoustic Attenuators?

Acoustic attenuators — sometimes called silencers — are devices designed to reduce the transmission of sound through ventilation systems, ducts, and external plant openings. They’re commonly used to:

- Reduce fan or motor noise in HVAC systems

- Control tonal noise from air source heat pumps and condensers

- Mitigate sound from generators, chillers, and mechanical exhausts

By controlling both volume and tone, attenuators play a vital role in achieving acoustic compliance on noise-sensitive sites.

Understanding BS4142 and the Role of Acoustic Attenuators

The BS4142:2014+A1:2019 standard is the UK’s benchmark for assessing industrial and commercial sound. It compares the noise from plant or equipment (rating level) with the local background sound level.

When plant noise is too high — or contains tonal, impulsive, or intermittent characteristics — the standard applies penalties that can tip your results into “adverse impact” territory.

Acoustic attenuators help reduce:

- Overall noise levels (dB LAeq)

- Tonal characteristics, which attract additional penalties

- Low-frequency energy, often problematic in residential areas

If your BS4142 assessment shows exceedance of background sound levels, well-specified attenuators can reduce emissions to a compliant level — often avoiding planning refusals or the need for costly post-installation mitigation.

How Acoustic Attenuators Work

Acoustic attenuators work by forcing sound waves to pass through specially designed chambers, baffles, or absorbent materials. As the sound travels through these structures, it loses energy, resulting in quieter output.

🛠️ There are two main types of attenuator:

- Dissipative Attenuators – Use acoustic infill to absorb sound energy (ideal for broadband noise)

- Reactive Attenuators – Use chambers or tuning to cancel specific frequencies (ideal for tonal noise)

Attenuators are installed at the air intake or discharge points of mechanical plant or within duct systems. They are engineered to balance acoustic performance with airflow resistance.

Typical Projects That Require Acoustic Attenuators

| Project Type | Why Attenuators Are Needed |

|---|---|

| New residential developments | To reduce plant noise affecting nearby homes |

| Mixed-use or commercial blocks | Rooftop AHUs or VRF units create tonal noise |

| Restaurants, pubs, or clubs | Fans and kitchen extraction systems can be intrusive |

| Industrial installations | Generators or large-scale HVAC must meet BS4142 standards |

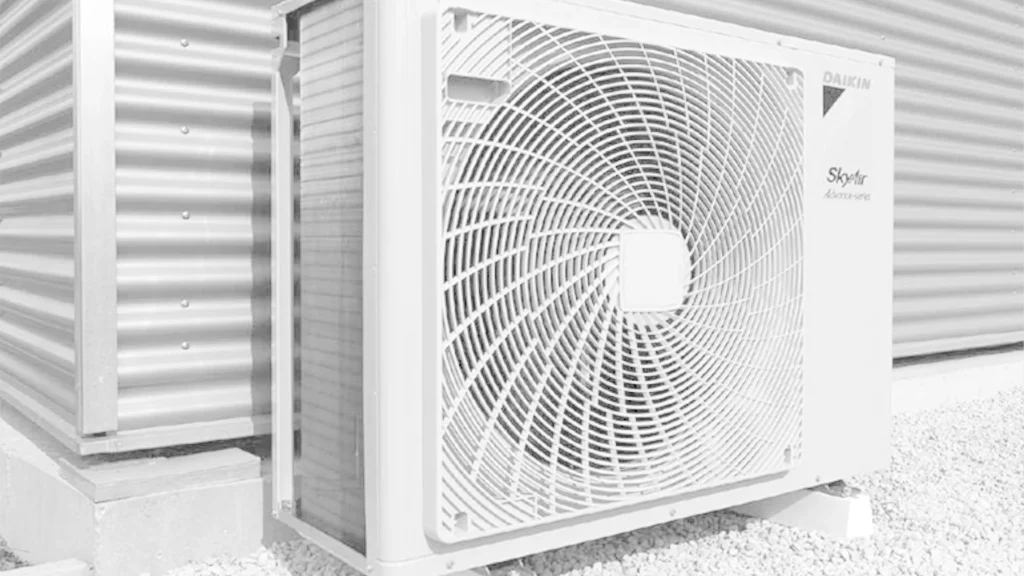

| Air source heat pump installations | Particularly sensitive in quiet rural areas like Hampshire |

Benefits of Acoustic Attenuators in BS4142 Compliance

When correctly specified, acoustic attenuators can provide attenuation levels of 10 to 30 dB, depending on frequency and size. Benefits include:

- ✅ Planning Permission Approved First Time

- ✅ Reduced Risk of Noise Complaints or Enforcement

- ✅ Avoidance of Penalties in BS4142 Rating Level

- ✅ Better Relations with Local Authorities and Residents

How to Specify the Right Acoustic Attenuator

Choosing the right attenuator isn’t just about picking one from a catalogue. It must be tailored to your system’s airflow and acoustic requirements.

🎯 Key Considerations:

- Insertion Loss Data: Performance by octave band (63 Hz – 8 kHz)

- Airflow Resistance: Avoid exceeding fan static pressure limits

- Tonal Profile: Address specific tonal frequencies if present

- Material and Finish: Weatherproofing and corrosion resistance for external use

- Installation Constraints: Available space, weight, and orientation

For accurate selection, your acoustic consultant will usually model the attenuator’s performance using proprietary software within a BS4142 framework.

Frequently Asked Questions About Acoustic Attenuators

1. Do all projects need acoustic attenuators to pass BS4142?

No, not always. However, where plant noise is close to or above background levels, or contains tonal elements, they’re often the most practical solution.

2. Can I use barriers or enclosures instead?

Barriers and enclosures are viable but may be bulkier, costlier, unaesthetic, or impractical in tight spaces. Attenuators often offer better airflow-to-performance ratios.

3. What if my site is in a quiet rural location?

In rural areas like parts of Hampshire, Devon and Cornwall, background levels may be very low. Acoustic attenuators are frequently essential to reduce emissions below these thresholds.

4. Can I retrofit attenuators after planning?

While possible, it’s more cost-effective and accurate to design attenuation into the early design stages of the scheme, and as part of your initial acoustic report for planning. Retrofitting can be constrained by space or design.

Avoid Planning Delays with Acoustic Attenuators

Too often, developers receive planning conditions requiring “details of noise mitigation” after submission – delaying schedules and frustrating contractors. By specifying acoustic attenuators upfront and including them in your BS4142 noise assessment, you can:

- Minimise planning objections

- Ensure mechanical plant operates within acoustic limits

- Reduce the risk of retrospective complaints or enforcement

- Avoid redesigning building services at a late stage

In short, acoustic attenuators are a proactive step toward smooth, complaint-free project delivery.

Get an Expert Acoustic Report with Attenuator Advice

Need a BS4142 noise assessment or unsure what acoustic attenuation your site requires? Our consultants provide detailed plant noise assessments, including attenuator modelling, planning-ready reports, and liaison with local authorities.

👉 Request a quote for an acoustic report or explore our acoustic services to ensure your development meets noise compliance from day one.